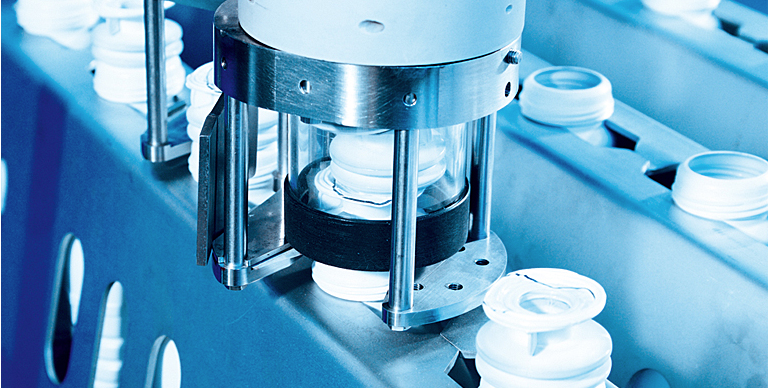

Working in the dairy industry is perhaps one of the most challenging in the food sector as a whole. Not only is food safety a big factor, but dairy products by their very nature have a limited shelf-life, which means avoiding downtime on filing, closing and other automated lines is absolutely essential for maintaining a healthy business.

JBT PRoCARE from JBT Food & Dairy Systems is focused on taking the element of uncertainty out of the equation through preventative maintenance programs, support and training, all with the aim of making sure downtime is kept to an absolute minimum.

With the specific requirements of the dairy industry in mind, JBT Food & Dairy Systems offers five different levels of PRoCARE programs, comprising inspections, remote support, preventative maintenance planning and maintenance kits, advance kits, and up to customized production support.

Bespoke maintenance

“For each and every PRoCARE contract, the customer can receive a customized maintenance plan based on their specific machine detailing all the specific parts and products they need to buy and how many hours they need to set aside for a replacement,” explains Jeroen de Vos, Customer Care Manager for JBT Food & Dairy Systems.

At a time when much of the industry is moving towards increased automation, he continues, companies can leave themselves open to the danger of not having people in place with adequate technical experience for knowing the optimum time for carrying out maintenance, which parts are needed and at which intervals.

PRoCARE, says de Vos, takes this uncertainty out of customers’ hands by providing them with a filled-in template of how to effectively maintain their machines and systems. “We can provide all of that information, the parts, and we can even provide maintenance kits which are packed in a sequential way where every single box has a purpose,” he explains. “We take all of that preparation work out of their hands, making it much more plug-and-play instead of having to keep all of that knowledge on board.”

Proactive approach

As an example of how PRoCARE can lend support, de Vos quotes a customer in the Netherlands with three JBT filler machines, which he describes as forming part of a complex, high-intensity line. “These are complex machines where we give a lot of support,” he says.

“This customer has several proactive shutdowns, so they have the same mindset as us which is that it is better to be proactive than reactive. What they are now doing is buying parts, so if they shut down they can exchange them straight away rather than having to shut down for three-four days. This is an example of how PRoCARE can help customers avoid unplanned shutdowns and downtime.”