BALL WARPER

Model:

Suitable for winding the balls for rope dyeing

Advantages:

High speed, easy operation

Low consumption, high productivity

Automation controlling system

For more details, please contact us

DIRECT WARPING

Model:

Advantages:

Speed up to 1.200 m/min

Beam diameter up to 1.400 mm

Available for staple fiber, filament,

glass fiber and other technical yarns.

For more details, please contact us

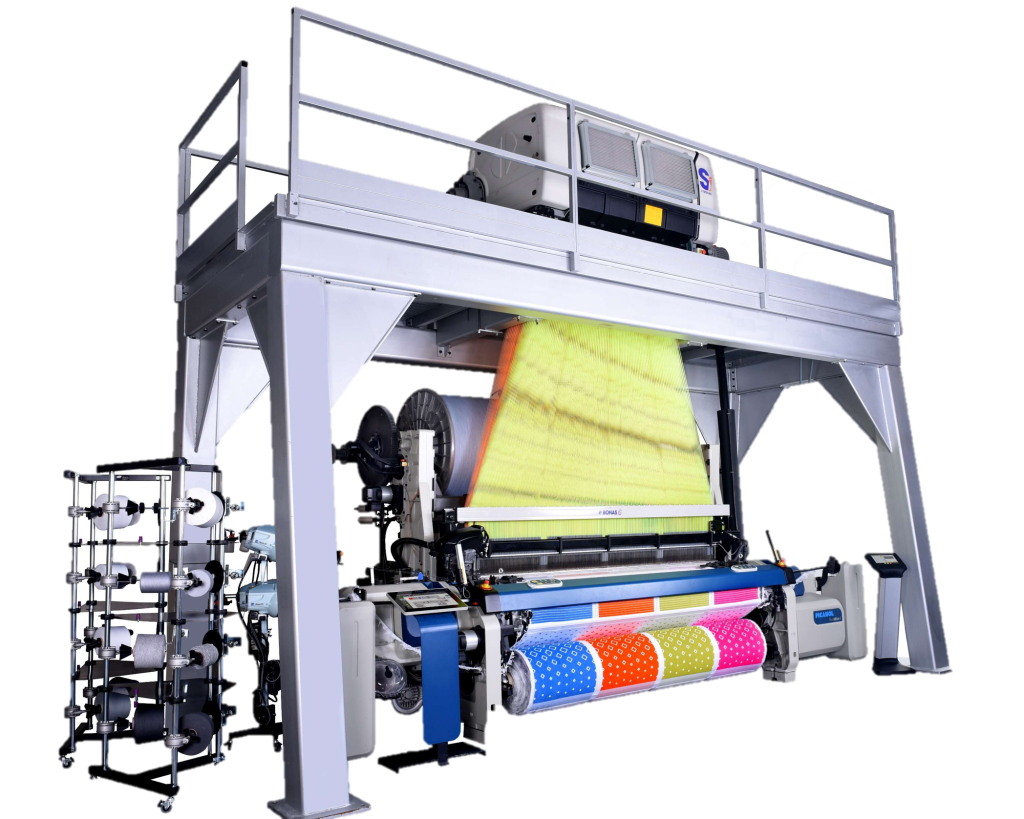

SECTIONAL WARPER

Model:

Used for the production of warps

for weaving with color repeats

Advantages:

Designed and suitable for the production warps with highest quality for high-speed weaving machines and the production of high quality fabrics.

Available for staple fiber, filament as well as for technical fibers.

For more details, please contact us

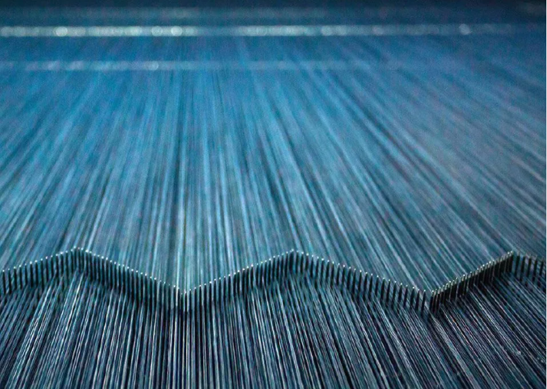

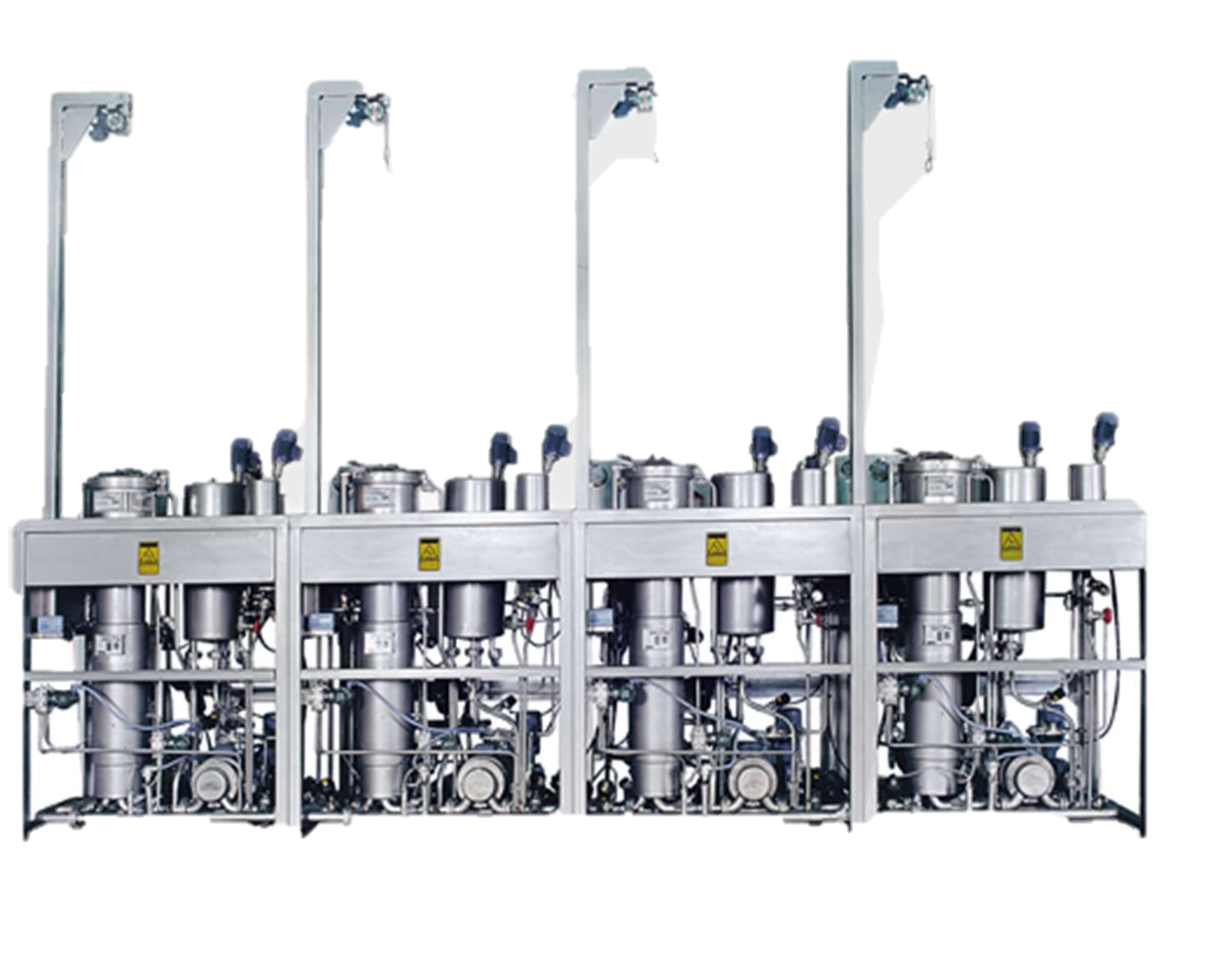

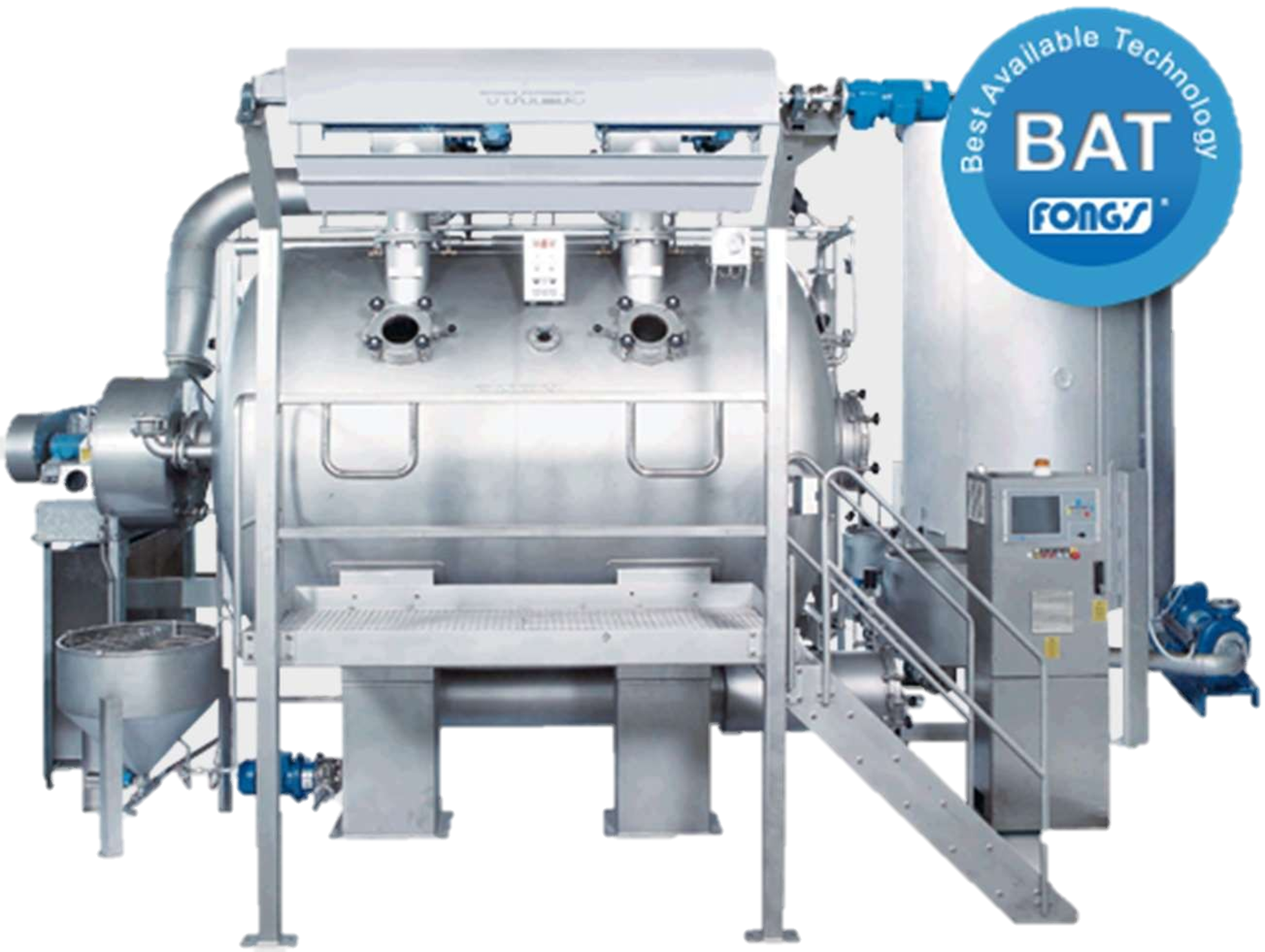

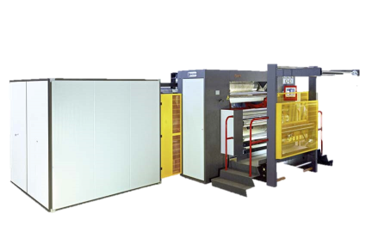

ROPE DYEING RANGE

Model:

Advantages:

For a certain range of yarn counts dyeing in rope form is still the most effective way. The newly developed ProRope dye range of PRO-SMH offers the most effective way with highest possible process reliability.

For more details, please contact us

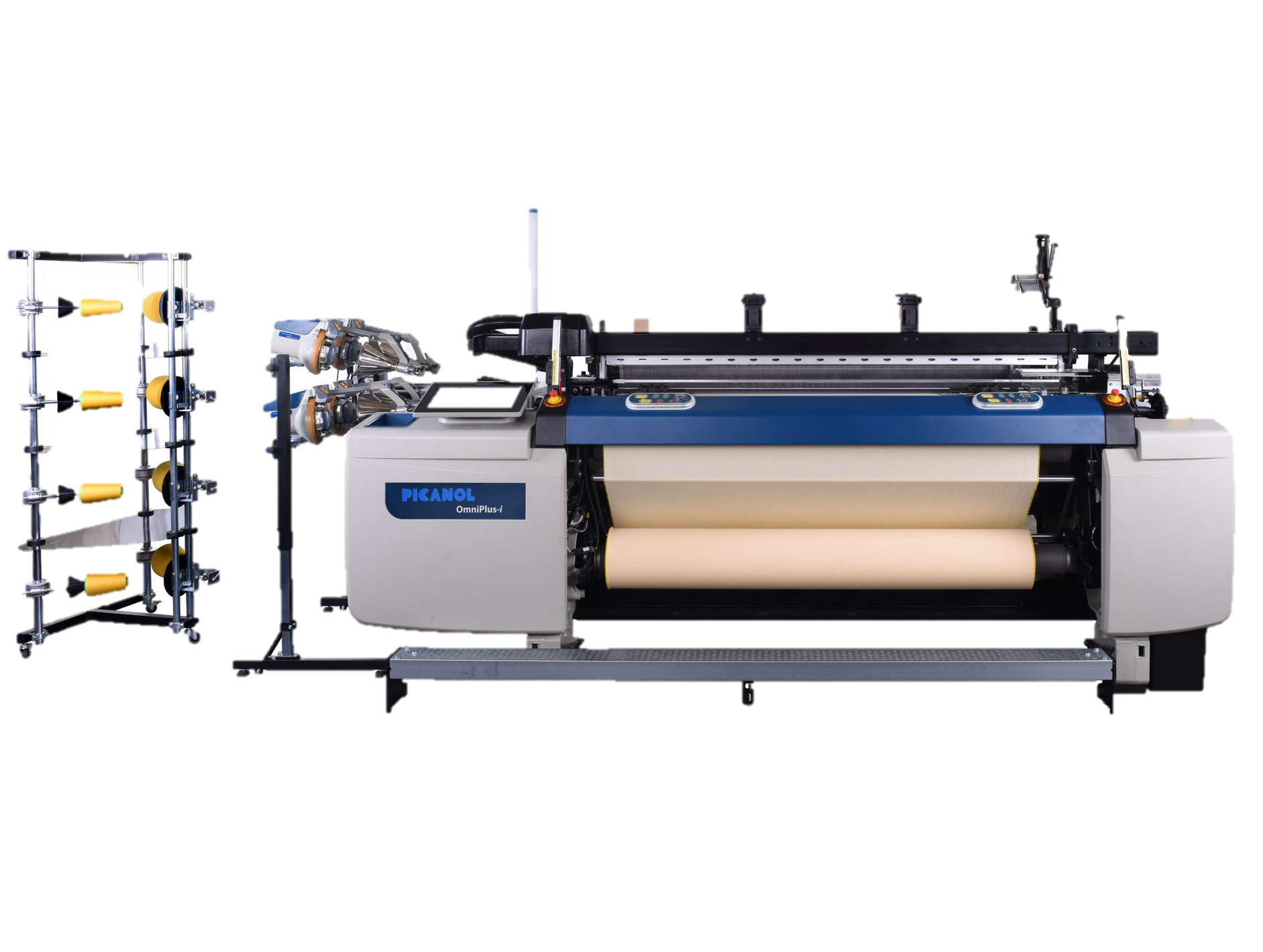

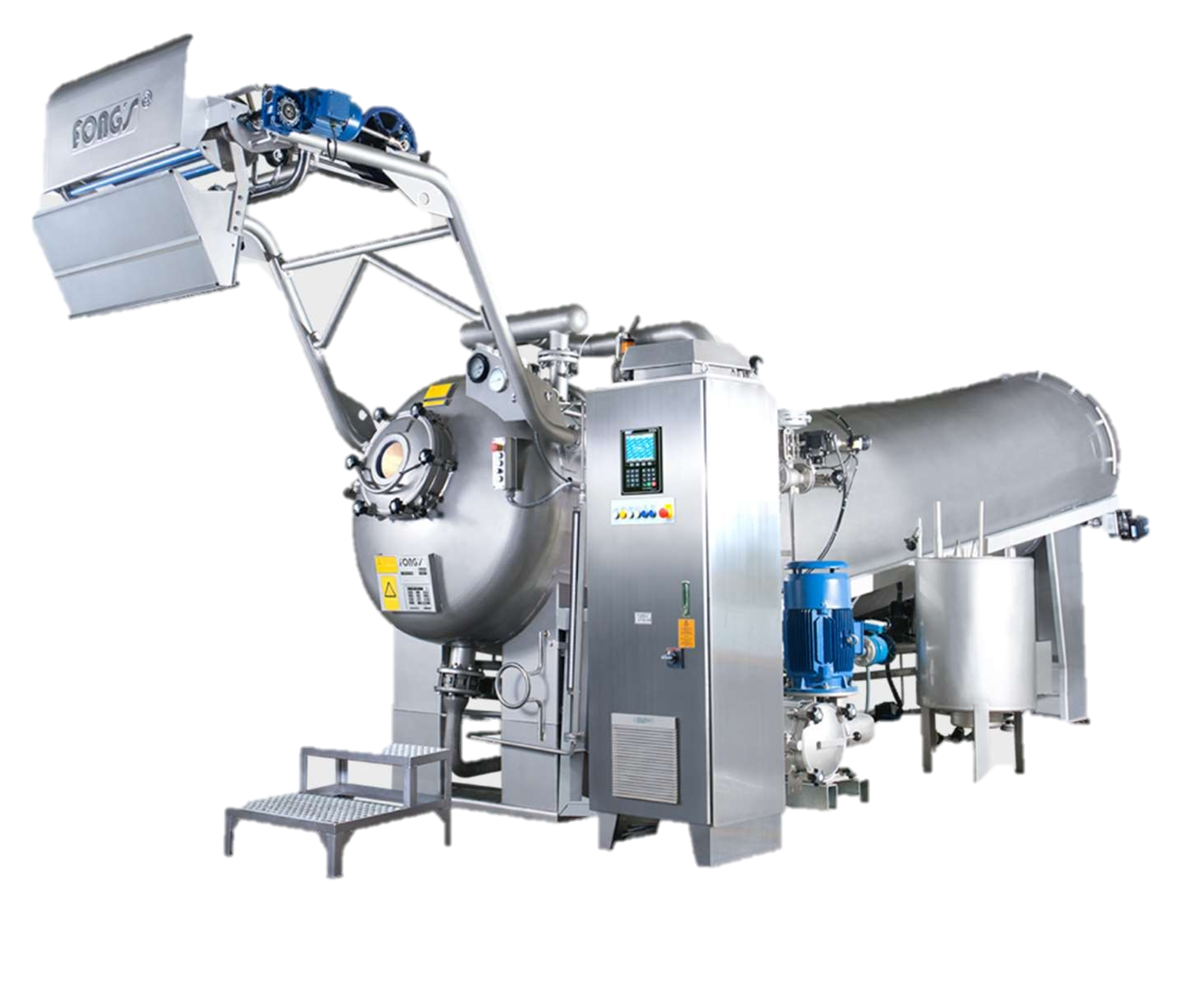

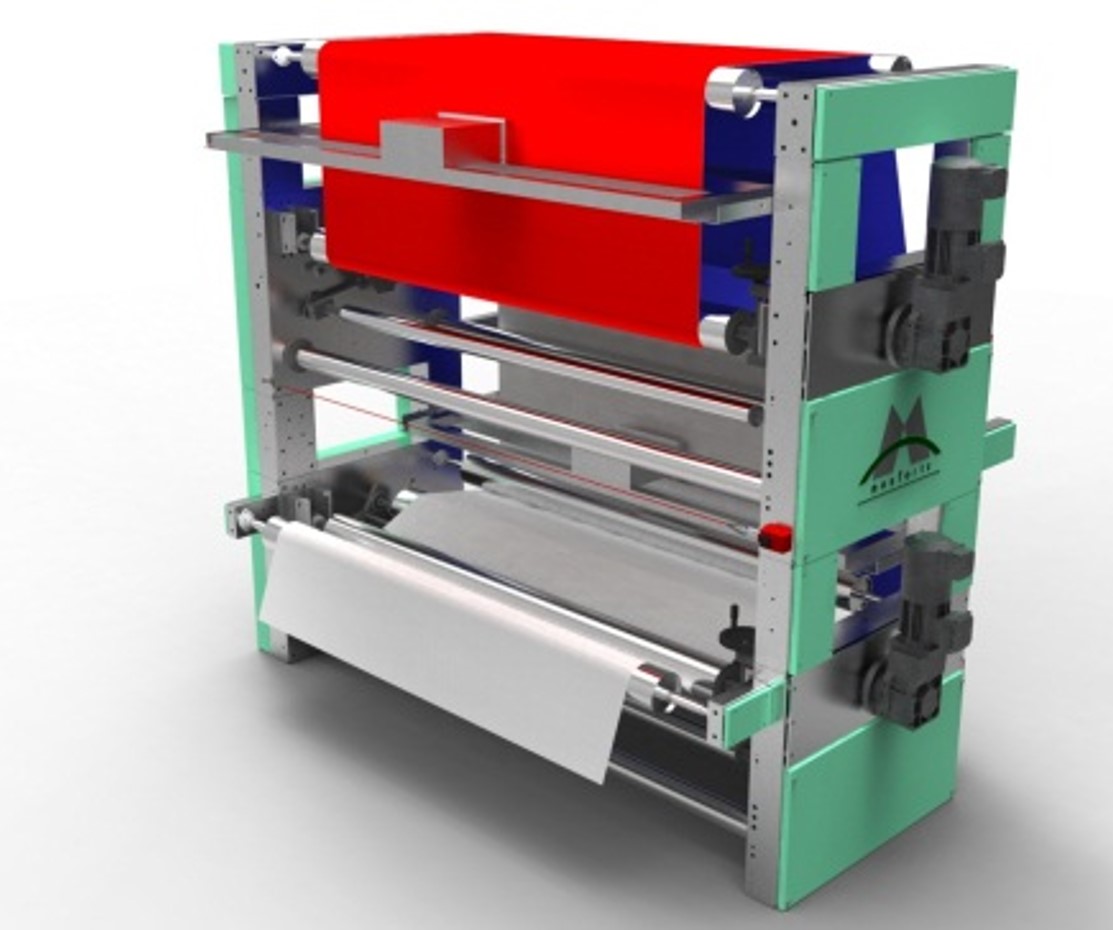

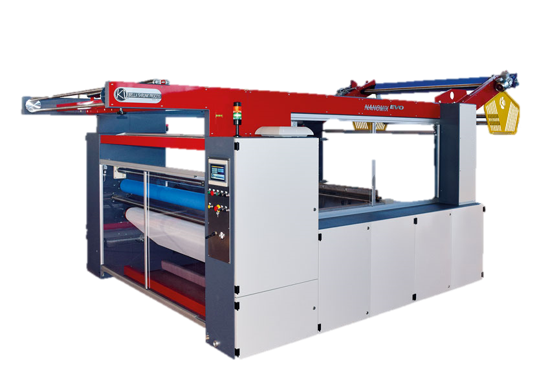

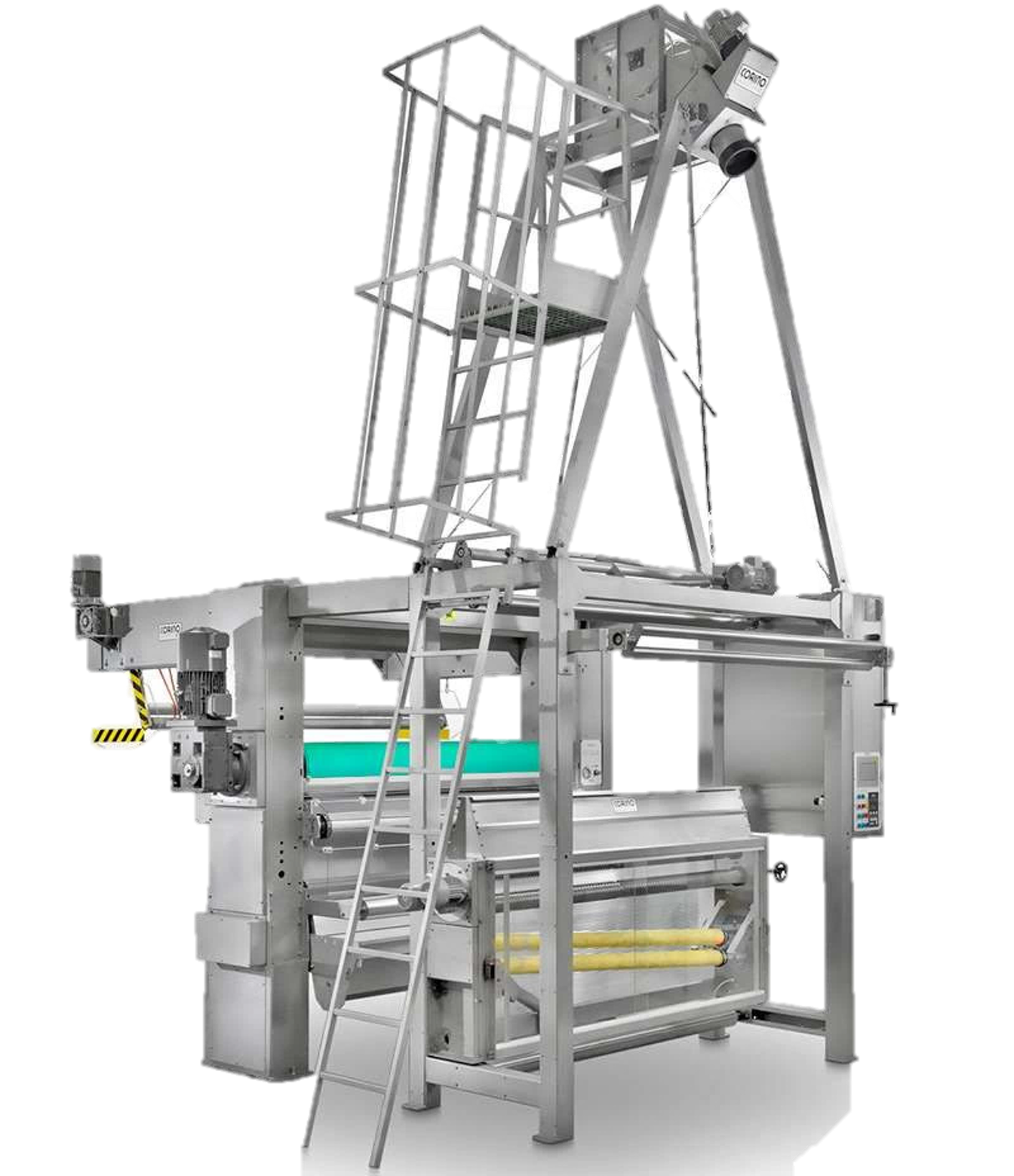

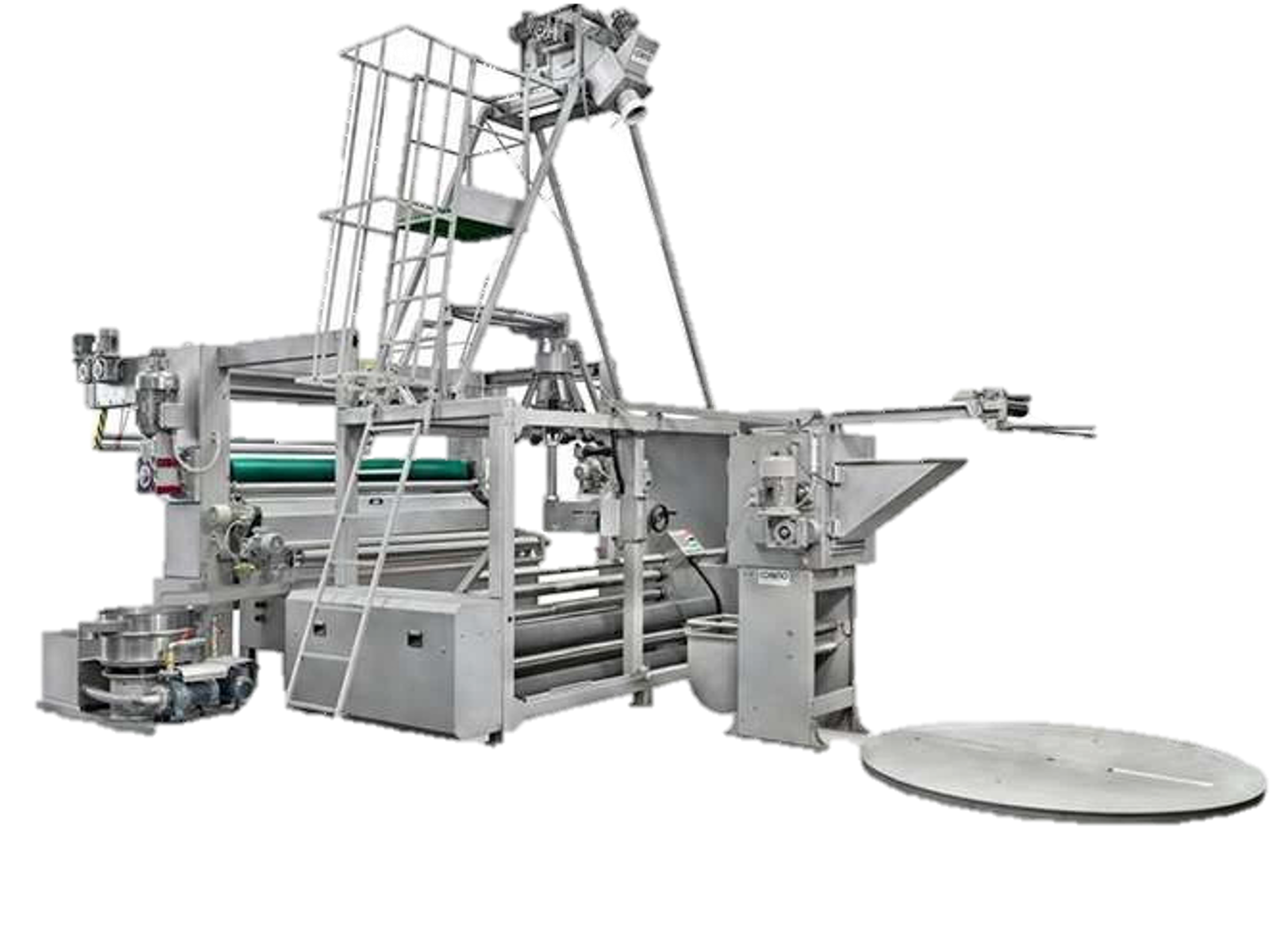

SLASHER DYEING RANGE

Model:

Advantages:

A key player in the field of dyeing

and sizing warp yarn for the denim production

The integration of Ultrasonic technology are

remarkable steps towards an increased sustainability

Increase the efficiency of such dye-ranges up to 70% with the double head stock system where two weaving beams are produced at the same time.

For more details, please contact us

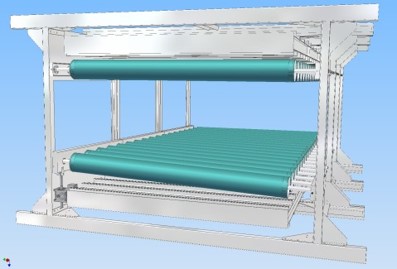

RE-BEAMER

Model:

Advantages:

After the rope dye process the ropes have to be untangled and prepared for the following sizing process. With its unique untangling device and highly efficient tension control the new PRO-SMH Re-Beamer offers best results to achieve that in a very safe and reliable way.

For more details, please contact us

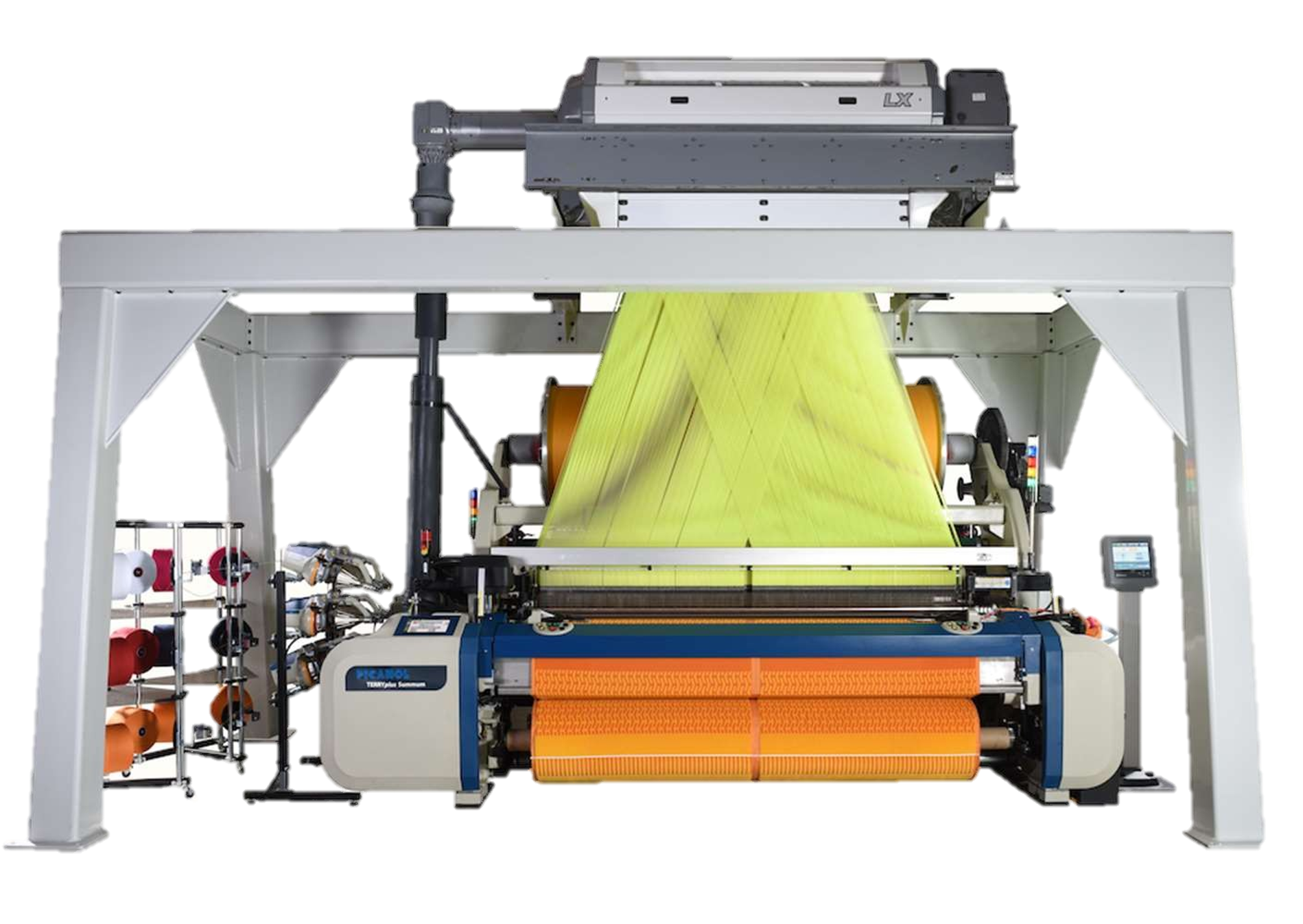

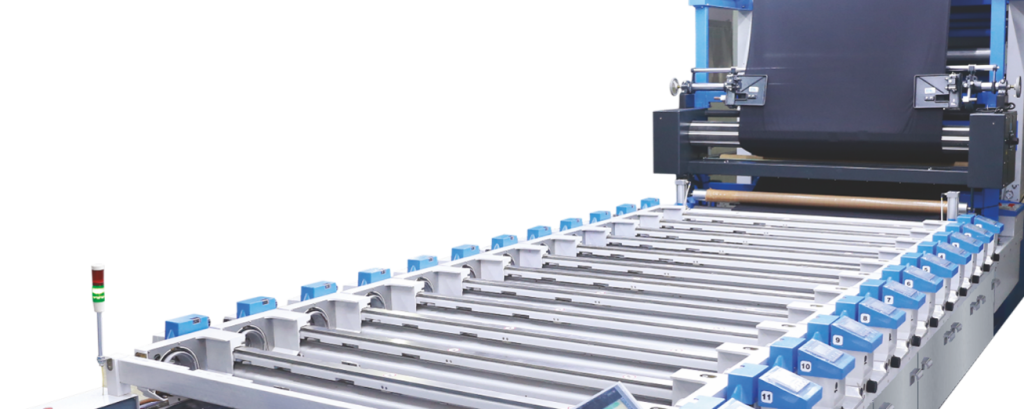

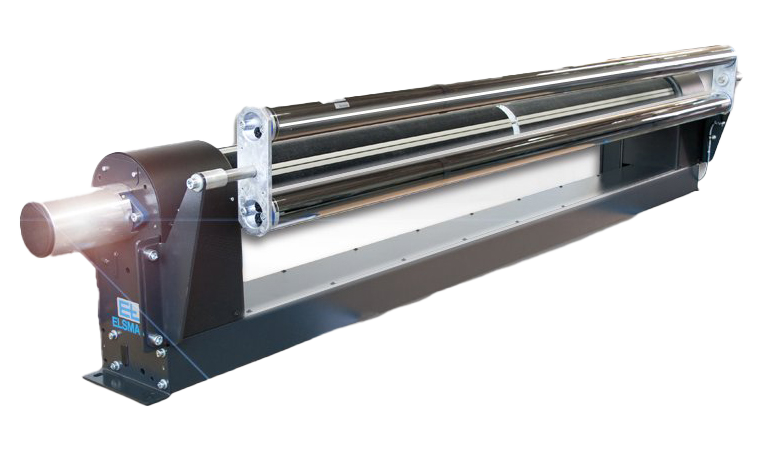

SIZING RANGE

Model:

Advantages:

High efficiency in the weaving process

Its sophisticated process and tension control

Available as one-box as well as two-box machine and can be combined with a wide variety of dryers

For more details, please contact us